rockwell hardness test experiment procedure|rockwell hardness tester pdf : Brand The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely Lauren Cat Nao Repara No Pijama So Me Come. 1 month ago. VXXX. No video available 56% HD 9:05. Naughty bunny ate chocolate filled with cum and even gave me her ass. 2 months ago. xHamster. No video available 64% HD 7:18. That Guy took me for a walk and I ended up giving my butt inside the car - (Rabuda doing anal) .

{plog:ftitle_list}

Motherland: Fort Salem. Raelle fights for her life, just as the Army and Spree converge on a secret Camarilla stronghold. Abigail and Adil's mission for vengeance escalates. In the season finale, the Camarilla brings the fight to Fort Salem. Raelle, Abigail, Tally and their allies are forced to make impossible, world-changing choices.

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell .

acl tear test video

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

rockwell hardness testing instructions

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .Steps: 1. Scale selection: It is very important to choose the Rockwell scale that matches the material’s type and required hardness. For example, softer metals are best tested with the .

There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the .Classification, process, differentiation and practical recommendations. Rockwell test procedure. In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter is measured. In contrast, the .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.

rockwell hardness testing guide pdf

rockwell hardness testing chart

The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation .

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared .

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should .

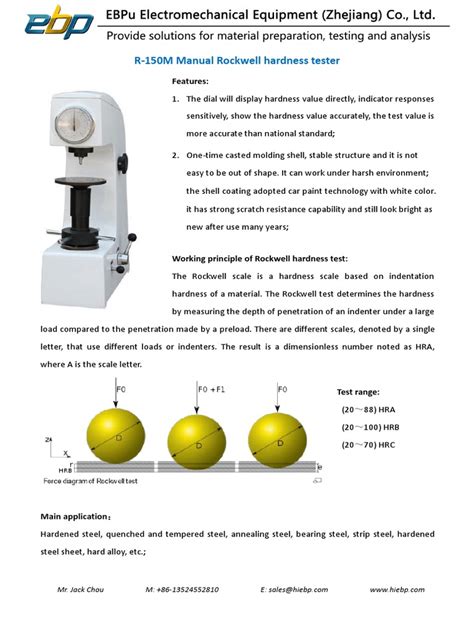

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . Tensile Test Experiment . ASTM E8M Tension Testing of Metallic Materials . ASTM E1090 Standard Test Method For Dicumyl Peroxide And Dicumyl Peroxide Decomposition .1. Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing 3. What are the advantages and limitations of Rockwell method of hardness testing 4. Where are Rockwell hardness test and Brinell hard test employed 5.The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an indentation test used for smaller specimens and harder material. This hardness test is preferred because it is simple, easy and relatively nondestructive .

Figure 3.1: Schematic principles of operation of Vickers hardness machine. MATERIAL & METHODOLOGY Material and Apparatus Hardness testers: Vickers microhardness. Test Specimens: Metal specimen from Experiment 5. Figure 3.2: Vickers hardness test. Procedure The hardness tests are carried out under the supervision of the lab instructor. Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. . ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard .

Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.3.1 Macro Hardness Test Methods 3.1.1 Rockwell Hardness Test The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load 𝐹0 (Fig. 1A) usually 10 kgf. When equilibrium has been reached, anThe Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520 [email protected]

To record the results during the experiment of each test we conduct for later calculations. Objectives: • • • Write a report on Hardness testing using two methods Rockwell and Brinell and describe them using different headings .

rockwell hardness tester procedure

VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond . Selected students will be invited to perform Brinell and Rockwell hardness test, . For Rockwell experiment, student has to calculate the depth due to major load (t) through the following formulas for each material tested: . The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors. This experiment was carried out in our university lab to determine hardness of metallic materials using Rockwell Hardness test Discover the world's research 25+ million members Rockwell hardness testing methods are defined in the following standards: ASTM E18 Metals, ISO 6508 Metals, and ASTM D785 Plastics. . The entire procedure requires as little as a few seconds (up to 15 for plastics), so the major advantage of the Rockwell test is that results are quickly and directly obtained without the need for a secondary .

Rockwell Hardness C Test was performed on a sample of steel provided and the experimental readings are recorded with inclusion of theory, procedure, pictures of the samples after testing is done .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured. ROCKWELL HARDNESS TEST: Rockwell test is developed by the Wilson instrument co U.S.A in 1920. The test consists in forcing an indenter of standard cone or ball into the surface of a test piece in two operations and measuring the permanent increase of depth of indentation of this indenter under specified condition. From it Rockwell hardness is .2. HARDNESS TESTING THEORY: Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: • Scratch tests are the simplest form of hardness tests. In this test, various materials are rated on their ability to scratch one another. Mohs hardness .

Rockwell Hardness Testing First developed over one hundred years ago, the Rockwell hardness test is a rapid hardness testing method primarily used for quality assurance and production control. It uses a diamond cone or steel ball to first apply a minor load of around 3kgf before an additional major load is applied; typically, exceeding 10kg.Virtual Procedure. Start the experiment by clicking the play button. Observe the movement of top knob and pressure applied by it on the test specimen. The top knob creates a hole in the test specimen and the load used is observed. An observation table is provided with different trials and mean rockwell hardness number is calculated.Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool forRockwell Hardness Test - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes Experiment No. 2 which measures the Rockwell hardness of steel, copper, brass and aluminum specimens. It explains that Rockwell hardness is determined by the depth of penetration of an indenter under specific loads. For steel, a tungsten ball .

rockwell hardness tester pdf

WEBCasal filmado a fazer sexo atrás de barraca de cerveja. Insólito aconteceu num hipódromo na Escócia. 23 de Junho de 2017 às 11:14.

rockwell hardness test experiment procedure|rockwell hardness tester pdf